CUSTOMER STORY

The Luxembourg Hospital Center (CHL) project represents a colossal endeavour aimed at changing healthcare offerings in Luxembourg. Beyond its architectural and medical ambition, the CHL project stands out for the scope of its collaboration among various renowned construction companies. Among the different subcontractors is the Association Momentanée CHL, a skill and expertise alliance including CBL, GIORGETTI, LUX TP, and GALÈRE LUX. This consortium is responsible for the major structural work and external networks, from the foundations of the building to its final level, thus affirming the commitment and capability of these companies to carry out projects of remarkable complexity and scale.

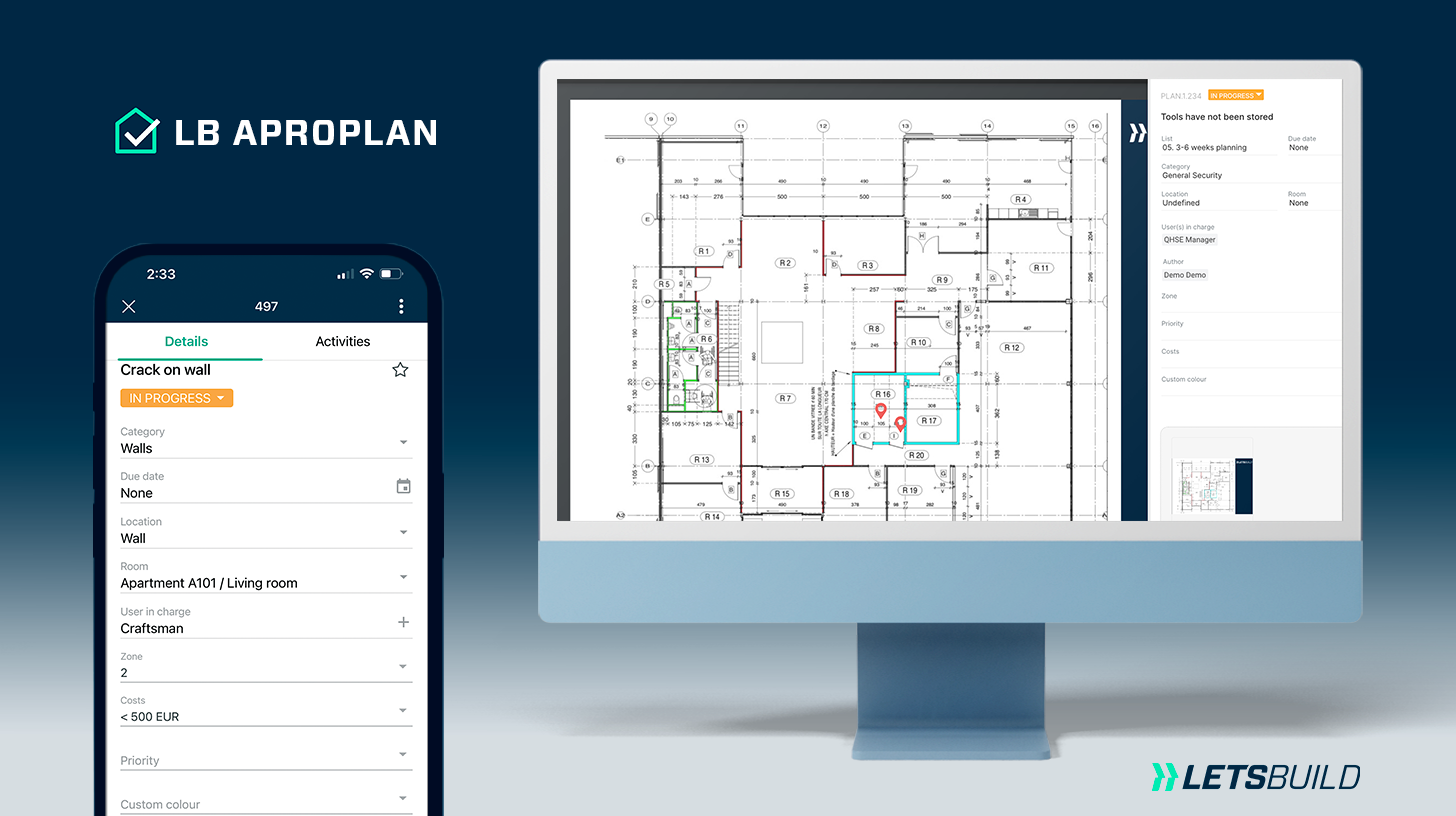

For this massive project, the choice of project management tools is crucial. Alexandre Bonvier, a construction engineer involved in the implementation and monitoring of quality control, is fully aware of this. His experience on large-scale projects like Cloche d’Or has allowed him to understand the critical importance of a reliable quality control system. It is in this context that he adopted LB Aproplan eight years ago.

The Project

CHL : A Significant Challenge

The Luxembourg Hospital Center project is ambitious: a new building is being erected on the current site of the old Maternity hospital, along the route d’Arlon between Val Fleuri and rue Federspiel. With a usable area of 54,158 m2, the new building will allow all current acute clinical activities spread across the CHL Centre and CHL Eich sites, as well as the National Institute of Cardiac Surgery and Interventional Cardiology (INCCI), to be consolidated on a single site.

Key figures of the new hospital:

- Total budget: €820,960,000 VAT included (based on Index 924.32)

- Usable area: 54,158 m2

- A building of 9 above-ground floors and 3 underground floors

- 476 beds (including 20 INCCI beds)

- 79% of single rooms

- 126 day hospital slots

- 18 operating rooms (15 in the CHL operating block sector and 3 in the INCCI sector)

- 6 endoscopy rooms

- 2 helipads

- Underground parking for 427 cars

The Tool

Selection and Deployment of LB Aproplan

The choice of LB Aproplan for this project was not made lightly. “It was easy to rally around LB Aproplan,” explains Alexandre, a construction engineer on the CHL project, referring to the familiarity and trust already established with the tool within his company. This adoption was all the more natural as the other companies involved in the project did not propose a more efficient alternative. This collaborative approach, involving different stakeholders from the project owner to the site manager, maximises the efficiency and quality of the work performed. Under Alexandre’s supervision, the team focuses on rigorous quality tracking and its detailed documentation through self-inspection forms developed on LB Aproplan.

The collaboration

A Well-Oiled Quality Control Team

At the heart of the action, the team consists of complementary “site” profiles and engineers, each playing a crucial role in monitoring and implementing quality standards on the site. Alexandre Bonvier, as a construction engineer, defined the Quality Assurance Plan and the Direct General Control Plan so that the team could ensure constant vigilance over procedures and quality standards. The expertise of each team member allows for the identification and resolution of quality issues, thus guaranteeing compliance with the project’s high requirements. The site managers, the direct link between the production teams and management, are responsible for monitoring the workforce and ensuring that the works comply with the plans. Their continuous presence on-site is essential for daily monitoring and ensuring that operations proceed as planned.

The Role of the Works Foreman in Managing Forms and Quality Monitoring

The site foreman works closely together to set up and monitor self-inspection forms, essential for quality management. Based on the Direct General Control Plan, this system specifies the frequencies and types of controls on the works, leading to the creation of specific form templates by area. The construction manager, visiting the site several times a day, completes these forms, thus ensuring continuous and precise control of the various project phases.

Interaction and Contribution of Site Managers

Site managers play an active role in filling out and enriching the self-inspection forms, thus capturing crucial data for maintaining quality. This collaboration ensures comprehensive coverage of monitoring and control needs, allowing for immediate responsiveness to any potential non-compliance.

It’s important to note that quality monitoring on a construction site, as the name suggests and regardless of the method used, truly embodies the art of building, of knowing how to build. This refers to the qualifications and skills of our workers, our teams, and their continuous desire to do well, to build well, as well as their willingness to learn and evolve. Each one contributing their part to the project, it’s crucial to highlight this work, the manual art of our workers and our teams. Without them and their daily work, there would be no construction site, no construction, and certainly no qualitative work.

The Work Team’s Approach

Quality First

Quality management on the CHL project is far from a rigid process; it requires flexibility and adaptability, principles that are dear to the team. Its personalised approach to monitoring and continuous improvement of quality relies on a strategic combination of standard directives and site-specific adjustments, managed with the help of LB Aproplan.

Adapting Quality Standards on Site

Quality on the CHL site is treated with special attention to adaptability. Alexandre, in close collaboration with the QSE (Quality, Safety, Environment) auditors, receives quality standards to adhere to. However, he has some leeway to adapt these standards to the specificities and real needs of the site. This flexibility is crucial for effectively responding to the unique challenges posed by such a large-scale project.

The Quality Assurance Plan (QAP) and the General Control Plan (GCP)

The backbone of quality monitoring lies in the Quality Assurance Plan (QAP), specifically focused on major works for this site. This key document is supplemented by a series of annexes and normative documents, forming a reference corpus for quality management. The General Control Plan (GCP) plays a central role in this organisation, defining the types of controls to be carried out, the self-inspection forms available in LB Aproplan, and the frequency of these controls. This structure allows for precise and adapted management of quality control activities, ensuring that all aspects of the project are monitored and adjusted according to the requirements and realities of the site.

A Dynamic and Collaborative Methodology

The site’s approach is distinguished by its dynamism: “Regularly, a point is made with the QSE auditor, and we extract the forms and non-conformities, and we make an impression at the instant T of the platform to ensure a follow-up of the points. LB Aproplan, is a living app.” This frequent review ensures that all stakeholders have the most recent information and that quality monitoring is continuous and reactive. The ultimate goal of this methodology is to maintain a live and up-to-date database of all quality measures, thus ensuring total transparency and continuous improvement throughout the project.

Regularly, a point is made with the QSE auditor, and we extract the forms and non-conformities, and we make an impression at the instant T of the platform to ensure a follow-up of the points. LB Aproplan, is a living app.

Some Reluctance Despite the Results

From Paper to Touchscreen

User Experience

The daily use of LB Aproplan is primarily through smartphones, a choice dictated by practicality and efficiency. “The phone is perfect!” exclaims Alexandre, particularly appreciating the speed and real-time aspect of the application. This mobility allows him always to have access to his documents, plans, and forms, a revolution compared to traditional methods.

One of the main challenges encountered on-site is not so much the resistance to change but the adaptation to modern technologies, especially touchscreen interfaces. Alexandre notes a generational gap in adopting digital tools but acknowledges the vital importance of a high-performance platform like LB Aproplan for the project’s success.

It’s not so much a mentality problem; everyone knows that for a project of this size, you need a high-performance platform, otherwise, you waste a lot of time. People are convinced of this; it’s more about each individual’s comfort with touchscreens.

This quote highlights an essential reality: the recognition of the need for an effective platform for project management is unanimous. The real barrier lies in familiarising with the touchscreen interface, a challenge that transcends generations within the construction teams.

The solution to this technological challenge largely relies on smartphone use. The mobile device becomes a central tool in the daily management of the site, thanks to its portability and its ability to centralise many functions essential to project management. The LB Aproplan platform, optimised for mobile use, allows Alexandre and his team to stay connected, access critical information in real-time, and make instant updates on progress and quality controls.

“One of the major advantages is the speed and the ‘real-time’ aspect of the application. You can put 3-4 people on it, have an overview,”

This ability to collaborate in real-time, share information, and simultaneously visualise work progress by several team members radically transforms traditional work methods.

I never walk around with a paper plan. I go to all my projects, my documents are sorted, structural engineering and different folders, execution plan, formwork plan, the different zones, the different levels, and I find all the formwork plans, all in 4 clicks.

By leaving paper behind for digital, Alexandre benefits from unprecedented organisation and accessibility of his work documents.

This transition to digital, embodied by the intensive use of the phone, demonstrates a saving of time, effort, and a notable improvement in responsiveness and precision in daily task management.

LetsBuild

Close Proximity to Our Teams

What truly distinguishes LB Aproplan in Alexandre’s eyes is the direct interaction and ongoing support provided by the LetsBuild team.

What convinced me was that we had more interaction with you than with others.

This closeness has led to numerous improvements in the application, making it even more suitable and efficient for the specific challenges of the site.

We would like to express our gratitude to Alexandre Bonvier for the precious time he has given us and for sharing his experiences and insights on implementing these advanced technologies in the CHL project framework. His expertise and perspective on integrating and optimising digital tools in quality management and project coordination are not only inspiring but also educational for the entire construction community.

Alexandre’s testimony perfectly illustrates the positive impact that such innovations can have on managing large-scale projects. His contribution to evolving work practices towards more modernity and efficiency highlights the importance of openness to new technologies and real-time collaboration in the sector.

Once again, thank you to Alexandre for his commitment, vision, and willingness to share his experience, thus helping to shape the future of construction with more connected, efficient, and successful projects.

How to see everything happening on site

Discover how management in 934 construction companies achieved peace of mind by ELIMINATING the use of text messages, phone calls, WhatsApp, email, Excel, paperwork, and formal reports.