Have you ever heard this edict? “A butterfly flapping its wings in New Mexico causes a hurricane in China?”

It’s called the butterfly effect.

In truth, this butterfly example is a bit of an exaggeration, but the underlying principle is not; small changes can have large consequences. And those large consequences become impossible to predict the long time runs on. Now map this concept to construction projects and our traditional waterfall planning method.

Free eBook: Lean practices for construction professionals

What researchers have noticed is that performing 100% of the design and planning effort before we break ground falls short.

Because of the size and length of construction projects, we get caught by the butterfly effect time and time again.

Defensive design

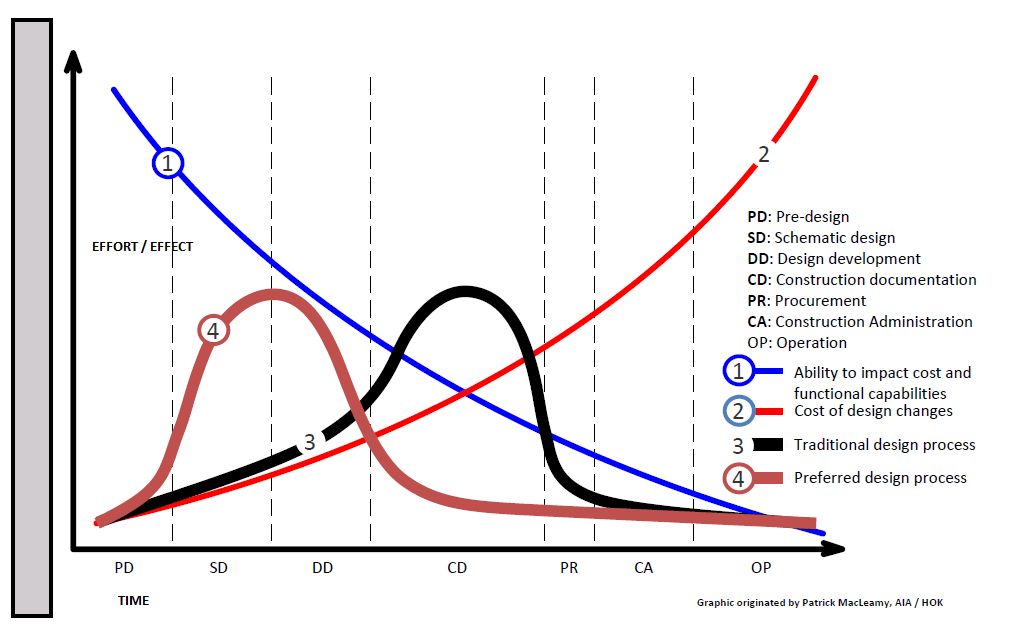

In 2004, Patrick MacLeamy produced a set of curves that would firmly solidify the problems of our traditional design-build approach. It’s called the MacLeamy curve.

The MacLeamy curve draws our attention to the fact that much of the design of a typical construction project occurs at a time when changes to the design are costly. On this graph, this is where red and blue lines intersect.

MacLeamy explains in the video below that designers are doing what he calls “defensive design”:

A new approach was needed to shift the design work (and the curve) back toward the early stages of the project when changes are not so costly and the ability to impact the project outcomes is high, as well. This is where lean construction comes in!

What is lean construction and why it matters

It has been around since the late 1990s but maybe you’ve never heard of lean construction. Perhaps inspired by the trend in software development toward designing and coding software in bursts incrementally, the developers of lean construction came up with a method to produce a predictable workflow on construction projects, taking ideas from Toyota’s Production Line System.

Lean construction is a new approach to building that is iterative. Planning, design and building are done in smaller chunks one at a time with a detailed approach called “the Last Planner Method.”

Rather than perform all of the planning and design upfront, then move on to building (what we call the Waterfall Method of project management), in Lean, work is planned, designed and scheduled in a weekly fashion, incrementally.

Read also: Pull planning in construction – 101 guide

Lean planning in construction is based on the commitment to deliver a certain element of work and element of time per day starting from the end and moving back to the beginning lean construction is all about collaboration. It’s a real wake-up call from the traditional approach in construction where Owners lay out the requirements and Contractors go out and build, only discussing when there are issues or setbacks.

Instead, we invite all parties to the table to plan, design, estimate, budget and optimize. All stakeholders collaborate and plan together; owner, contractor, sub-contractors, designers, engineers, schedulers, cost engineers, etc.

The team will often prototype a design, rather than forge ahead and build. Prototyping provides us with a visual and functional model that we test and evaluate. Today’s advanced BIM software tools are allowing us to quickly prototype designs and walk through them virtually.

Rather than pricing a design, the team designs to the allotted budget. Cost and work optimization is one of the biggest benefits of lean construction. Studies suggest adopting lean construction can save up to 30% of the project cost.

Collectively the team will come up with opportunities, suggestions, debate with the owner, build scaled models, mockups, and be involved with end-users & clients to gather feedback.

What are the main principles of lean?

So let’s dig into a bit more of what lean construction constitutes. One definition cites lean construction as “a philosophy for working based on continuous delivering of better value to customers whilst increasing business profitability and competitiveness”.

Essentially though lean manufacturing is a culture and should be employee-focused. Any firm adopting the lean principles will depend upon its staff spotting hidden issues and dealing with them, cutting waste, assessing work practices and looking for ways to work more efficiently. This should be done through teamwork, where workers can coalesce around a single purpose and all work towards the same goal identified by the company.

In this respect, the idea of lean cannot just be dumped on a workforce. There has to be buy-in from staff who understand the reason they are adopting this approach and the benefits it can deliver.

The idea of lean, as first pioneered by Toyota, is that it offers a clean, safe and efficient working environment. The philosophy is broken down as 5 S’s. In English, this is generally translated as sort, set in order, sweep, standardise, sustain. Let’s look at those in detail:

- Sort – Get rid of anything surplus to requirements, so that could be tools, documents, or materials

- Set in order – Establish a place for everything and keep each object in that particular place. Staff must have easy access to anything they require.

- Sweep – This essentially involves ensuring the workplace is kept tidy

- Standardise – Work practices must be clearly defined and consistent across the board.

- Sustain – Once you have established a process that follows these, the idea is that you should sustain them.

What is the lean philosophy?

So what is the best way to go about adopting a lean construction approach? To begin with, you need somebody in the company who can act as a champion for implementing the change. Implementing new ideas can often be met with great resistance, particularly in an industry like construction where there is an embedded resistance to change and new concepts.

So ideally the individual needs to be someone with the strength of character to persuade people of the benefits of a lean approach. And, of course, whoever is leading the change needs to have the full backing of management.

To unite people under the same cause you need to convince them about the reasons you are adopting lean principles. In this respect, ideally, it’s good to identify a trigger reason for shaking things up. Due to the general nature of construction, a crisis is often never too far around the corner. So if you are thinking about lean, the next time a major issue crops up or a project comes unstuck, this could be an opportune time to pounce to convince your staff that a new approach is needed.

Once you decide to take the plunge, it’s important to kick things off with a highly visible activity and ensure you get immediate results. The problem you want to avoid though is simply trying to cut costs or make people do things faster. This is bound to create a backlash among staff and will not get things off to a good start.

Find here: Ten benefits of prefabricated construction

After you have got things off the ground though, it is important to keep up the pace and widen the scope to bring people with you. This is how lean will work successfully as ideally, it should bring about new opportunities for improvement continuously.

Lean has also to do with understanding in greater depth what the client requires. So it isn’t just about what to build but the reasons behind it, as well. If you can understand and appreciate this, it will help your relationship with a client.

Ultimately, adopting the principles of lean construction will not be for everybody. It may be the case that it is not quite right for your business or the idea of it is just not suited to your business as you cannot see there will be enough. Or maybe your business is already as efficient and lean as you need it to be – in which case, well done and as you were.

But for many construction firms, as can be seen through numerous examples, productivity and efficiency are still concepts that elude them. In this respect, attempting to adopt at least some of the principles of lean could make a significant difference.

There’s a huge amount of information and advice out there, so there’s no time like the present to give it a try. For some contractors, it could even be the difference between survival and failure.

Lean construction focuses on reducing waste

A big focus of Lean Construction and Lean Planning is to reduce waste in Construction. Research estimates that only 40% of all budget on a typical construction project is spent on value-added activities, while the remaining 60% of the budget is non-value adding actions, such as:

- Waiting time (materials, sign-off, previous work, etc.

- Inventory stockpiling

- Correction of defects

- Overproduction (activities not on Critical Path)

- Inefficient transportation

- Poor planning

The collaborative nature of Lean Construction makes maximizing value and eliminating waste much easier.

One of the principles of Lean Construction is called “the Value Stream”: the team aims to adopt the most effective process, achieved by the minimum number of value-added steps.

What does a Lean Construction Schedule look like?

In a Lean Construction project, we often build a straightforward milestone schedule for the chunk of work we’re focused on. This is different than traditional CPM schedules.

A lot of the planning and scheduling in Lean Construction is termed “pull-planning.” In pull-planning, we plan backwards, starting with the end in mind and defining the backward steps incrementally.

In pull-planning, key milestones are broken down into 3 or 6-week lookahead schedules keeping the focus on the work in front of the team at the moment.

We ask:

- What do we need to be ready?

- What decisions need to be made?

- What materials to allow the work to happen?

The 6-week schedule is planned out by the individuals who will perform the work – the contractors and tradespeople.

In scheduling, team members answer either:

- Yes I can do that

- No, I cannot do that, because… then this because becomes a new constraint.

Then the team works on how to remove that constraint.

Conclusion

How do you go about implementing Lean Construction? There are lots of ways. But get ready to turn your familiar construction build routine upside down. Once you adopt it, Lean Construction is not just how you work, but how you live. Start by getting involved in Communities of Practice. Plan a visit to a Lean Construction project site, attend presentations or a bootcamp. Some even offer simulations on approaching a lego build with the Lean methodology.

More to read: Last Planner System in Construction

However, you decide to get your feet wet with Lean Construction, make sure you approach it with an open mind. As inventor/engineer Charles Kettering said: “There exist limitless opportunities in every industry. Where there is an open mind, there will always be a frontier.“

About the author: Michael Lepage, PMP is the founder of Plan Academy, an online training platform built for project controls professionals with on-demand courses on Project Controls, Planning & Scheduling software, Delay Analysis and project management for heavy industries. Try our flagship Primavera P6 course.