New developments in construction are coming forth regularly, mainly with the focus on sustainability. One of these innovations is the construction method through 3D printing which has the power to change the face of development tremendously when fully evolved.

The name describes exactly how this building practice works, 3D Printing means basically to build a home with a 3D printer. If you have not heard of 3D printing or seen it in action, this might be difficult to imagine as the thought of such a home might bring an unstable, fragile, paper thin home to mind. 3D Printing is, in fact, an innovative technology where the strength of the construction depends on the materials used.

First, we need to understand that this is a form of smart technology, which makes the concepts already a bit easier to understand, as we all know that with smart technology anything is possible these days.

Construction with the help of a 3D printer includes a wide variety of applications within the building sector. Different techniques use 3D printing to form the basis of the building construction or to create an individual component within the fabrication.

Fabrication of homes, components needed in buildings like panels and columns, bridges, civil infrastructures, and sculptures have all been demonstrated with 3D printing. The process can either be done on or off the site.

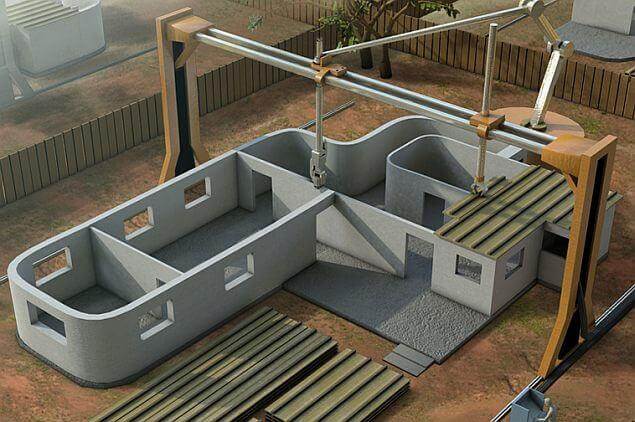

The actual 3D Printer is best described as an industrial robot with a gantry crane system that moves around through an autonomous vehicle system. The concept of using robots to build homes made its way between 1950 and 1995 when robotic bricklaying was explored. After this, the 3D printing development and research started during 1995, following the first generation during 2000 – 2010 and the second generation from 2010 and onwards.

What this printer does when building a home is print out the walls, partitions and building envelopes of the house with a durable concrete material. Once the concrete structures are printed out and dry, the workers paint the home, install the wiring and add the roof. Most of these printed structures are printed hollow so that it can get filled up with insulation and other selected materials.

In a situation where there is no need for a strong architectural design, the 3D printing process is done very fast, and the quality it delivers is extremely high which provides results that can last up to 175 years. Building structure that is done through 3D printing has many benefits due to the time it saves, minimum labour requirements and less pollution it produces. During the development process, the integration of functions performs better which allows for the ultimate accuracy, leaving little space for mistakes and waste.

3D Printing has hope for the future

3D Printing has been explored in many institutes around the world through different approaches with the aim to improve the methods. One example of two construction companies merging with the idea to promote 3D printing development is the Sunconomy construction company from the USA and Apis Cor from Russian 3D printers. The goal of these two merging companies is to develop homes that are affordable, smart and sustainable that can be created in only one day. Imagine what a goal like this being reach can do for the future of our planet! Not only will the carbon footprint that construction leaves on earth minimize, but the lack of housing world wide will decrease, providing people from all over with a better lifestyle.

The Apis Cor 3D printing Machine

The best way to understand how 3D printing homes might make way into the construction industries on a big scale is to explore the device itself. The 3D printing machine from Russia is very energy efficient as it consumes only eight kilowatts of electricity while building. The waste that gets produced during this process is very little if not none at all. Building on site with this machine is not the problem because it is light weight which can easily be loaded and moved on the back of a truck. Besides from the fact that the 3D printing process is fast, the machine itself can be set up in no time as there are no added rails and can still operate in an area of 132m².

How would 3D Printing effect the construction worker?

This method of construction might seem like the replacement of the construction worker, but this does not have to be the case, as workers can be retrained to learn the operation of the machine. Therefore, it can be said that the labour of the construction worker has just gotten easier. Work on other parts of the house is still needed, because flooring, roofing, energy installations, painting, etc. is not done by the machine. Rather than looking at the 3D printer as being a replacement of the construction worker, we can get excited about the fact that more homes will get produced in a fraction of the time, not decreasing the job openings, but increase the majority of constructions.

Most homes and significant building construction usually ask for big budgets and loads of time to plan which in many cases can put the job load on hold. In the case of 3D printing, we are looking at cheap and well-organized constructions plans which will offer a quick flow of work for the average on site worker.

Want to learn more?: Modernise Or Die: The Need For Change In Construction

The green movement can benefit from the 3D printing homes development as it produces less waste during construction. If the interior of the house is kept eco-friendly through natural resources, the result is a great sustainable home. Rain water catchments and solar power can be installed to ensure efficiency. IOT devices can also be fitted in these homes because 3D construction is sure to be compatible bringing a smart home to life which increases the comfort and luxury of the resident. Another benefit to the homeowner is that the insurance cost on the home will lower because such homes will have a lower risk of natural hazards like fire and roof damage. Seeing that these homes are very sustainable, the conclusion can be made that these homes are not just very affordable to construct, but they make a great investment in the long run.

The 3D printing methods are not brand new to the industry, but only recently it is taking the momentum that it should. The development of the 3D printing homes is a revolutionary concept, and we can only imagine the great possibilities it will bring once it starts to take off in full action.

About the author: Matthew Smith for Fortified Roofing.