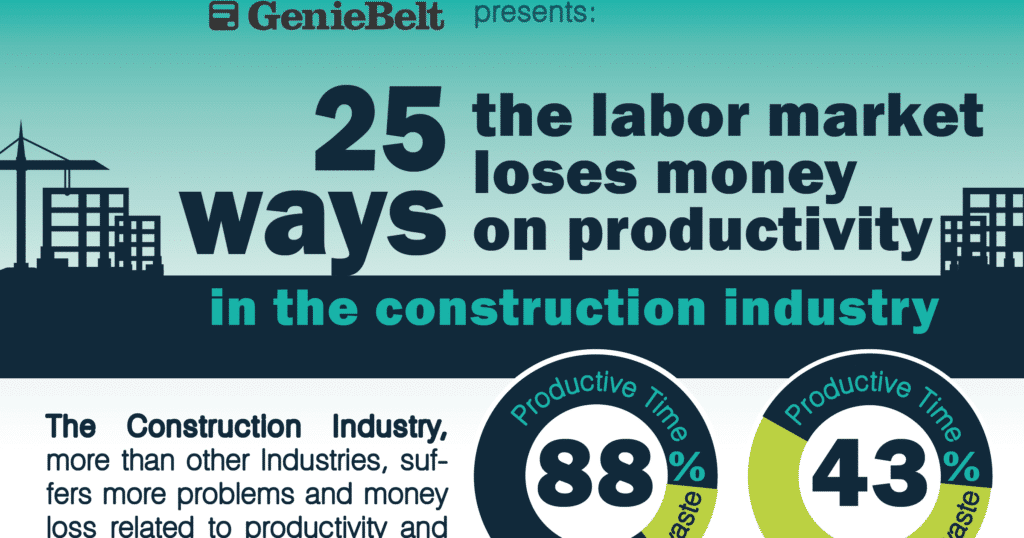

The construction industry suffers some serious problems and money loss due to low productivity levels, and high levels of waste or non-value added activities. The numbers range from 12% of productive time wasted in manufacturing to a much larger 47% in construction.

Potential labor productivity in the construction industry in the UK is lowered by:

– 3-6% because of accidents

– 10% because of material waste

– 30% because of re-work.

Overall, that makes for a striking 40-60% loss in terms of potential labor productivity.

What can affect productivity in the construction industry?

For the sake of clarity, we grouped them under these 5 areas in management:

- Scheduling and planning

- Leadership

- Manpower

- Workspace

- Site specifics

The relative impact of each factor on productivity can be summarized as follows:

Scheduling and planning

1. Overtime: Planning extended work days, with a schedule that goes over 8 hours a day and consequently longer work weeks causes lower productivity.

2. Concurrent operations: Introducing additional operations to a previous plan without controlled implementation can create delays.

3. Mobilize/demobilize: Moving resources on and off as a result of changes or delays can cause work disruptions affecting productivity by 25%.

4. Start/stop, shift changes and manpower reassignment: Unplanned stops over 15 minutes occurring in these circumstances can have about 30% negative impact on productivity.

Read also: UK could save £15 billion every year by lifting construction productivity

5. Errors and omissions: Any increase of the error factor means delays. When processes are not followed or are incorrectly carried out, they can cause changes performed in crash mode, dilution of supervision and fatigue and lack of motivation in the workforce.

6. Ripple effect: About 10 to 20% of productivity can be negatively affected by the ripple effect generated from schedule changes from other trades. It affects scope of work, schedule, shifts and more.

7. Late crew built-up: Alteration in the planned manpower loading produces delays in crew build-up due to lack of availability, shortage of resources or competition for resources.

8. Crew size inefficiency: When changing the optimal crew size, the original team effort is disrupted and consequently the rhythm and quality of the work are compromised.

9. Overmanning: When trying to make up for potential absenteeism or turnover, the risk is to overstaff. It may give a sense of higher productivity but in reality it’s just misleading.

10. Alternating, staggered or rotating work schedules: These types of work schedules are used to optimize craft hours, to attract labor to remote sites and to minimize fatigue, but they also create unusual shifts workers might not respond well to.

11. Safety checks: As important as they are, if general safety checks are not scheduled they can cause delays if carried out before, after or during certain operations.

12. Safety in hazardous site: Working in hazardous areas can create delays because of extra time needed to cool down or warm up the equipment, taking breaks or carrying out safety checks.

13. Logistics: If logistic controls and procedures are not fitting, a lot of troubles can arise in e.g. procurements and supplies delivery.

14. Tool and equipment shortage: If the amount of tools is not sufficient or their quality is faulty, this can have an impact as big as 50% on productivity

Leadership

15. Attitude and morale: Fatigue and low motivation caused by overtime work, conflicts in the workplace, changes in workflow or poor site conditions can impact productivity by 12%.

16. Dilution and supervision: When supervision changes, or when emergencies or accidents occur, they alter supervision and production management.

Manpower

17. Absenteeism, turnover and/or unpaid holidays: With a mere 8% absenteeism on the job, there is a 25% impact on productivity due to time and money used to find replacements, assign them tasks and allowing for them to learn.

Find also: McKinsey & Company – Welcome to the new era of construction technology

18. Learning curve: New crew members need time and guidance to perform well in a new task, and that affects the production rate of the whole team at least in the first week.

19. Area practices: Local customs and culture can change the way workers behave and perform and the time they spend on breaks and their schedule in general.

Workspace

20. Sticking of trades, joint, and beneficial occupancy: A lot of operations taking place in a restricted space can cause congestion.

21. Confined space: More breaks and security checks are needed when carrying out operations in workplaces with no ventilation or sunlight.

Site specifics

22. Weather events, season changes, shorter daylight hours.

23. Rain factor: Rain doesn’t have to mean that every task on site should stop, but extreme weather conditions can lower productivity by 25%.

24. Site accessibility: Interferences in the access to the site, like blocked stairways, roads, walkways or insufficient man-lifts.

25. Proximity to work: When working in a remote area where access to resources and tools is not as easy, distance can take its toll on productivity.

These elements, if underestimated, can seriously delay the delivery or compromise the result of a construction project. Budgeting is one of the most important elements to keep in mind when managing a project and is part of what makes it succeed or not.